Since 2006, our company has been committed to the production of helicopters. Motivated by the maxim to never stop pursuing your dreams, we subvert traditional design with innovation to guide the future direction of the helicopter model industry. Armor 700 continues the previous 17 patents of Miao. On this basis, we have five more innovative designs with independent intellectual property rights. This is also supported by the continuation of numerous exclusive innovative designs that have defined our place in the industry.

The Internet remembers everything and acts as a collective unconscious for humanity. We initially proposed the concept of reducing the height of the main rotor (TL45117) in 2011. This concept would focus the helicopter’s power around its center of gravity, thus increasing the helicopter's sensitivity and responsiveness. Until now, it has been used by many manufacturers. The Armor 700 also adopts these classic, structural strength and aesthetic designs on which our customers have come to rely. This design innovation can carry your passion to new heights as well.

Today's Armor 700 consulted the advice of many experienced players and made a mid-term change, launching V2 canopy and V3 armor. When ordering V3, you can specify the color of armor and the specification of tooth ratio. (Please ask the sales staff or check the manual for details).

The Armor canopy adopts a modular and separable design utilizing injection molding with high-strength material. This approach streamlines its aerodynamic appearance through an energy absorption collapse effect. It is conducive to heat dissipation and protection of electronic equipment and boasts an extremely low-cost loss. Bright colors and Taoist Chinese culture stickers set off this design, providing good visibility, brand recognition, and aesthetics throughout its flight.

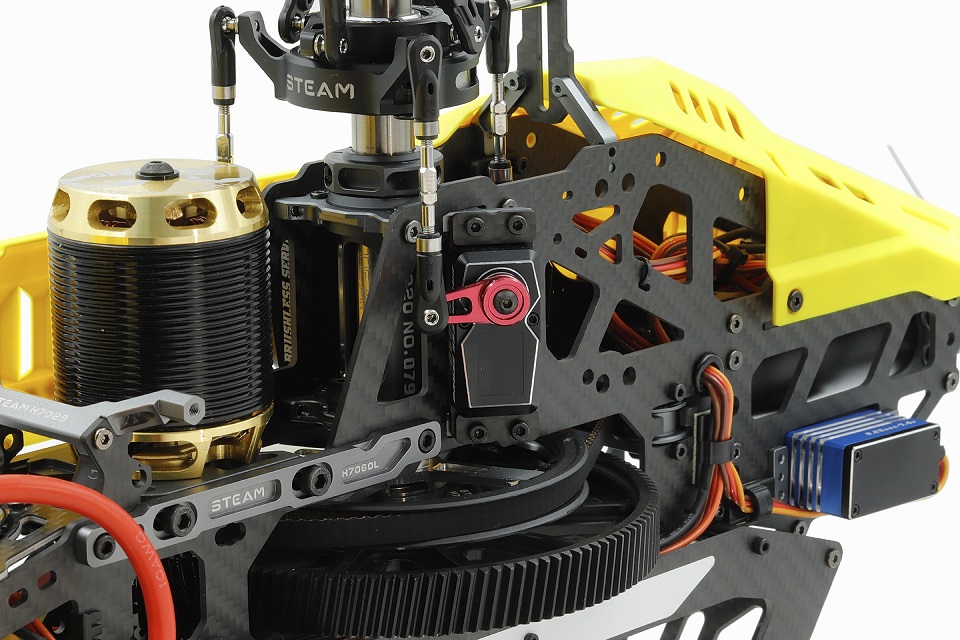

The main rotor housing uses two colors to mark direction. When adjusting the length of the linkage rod, avoid recognizing the wrong direction of the T-type diagonal bracing reinforcement structure. To activate the two-way lock, firmly hold the spindle. This design meets stringent flight load-bearing requirements, and effectively improves flight stability. The ball link with its stainless steel explosion-proof ring prevents cracking during violent flights.

In 2011, we pioneered the innovative use of angular contact bearings (TL8023) on helicopter models, which are now used in various parts by many manufacturers. This time, there are two double-row angular contact bearings in the main rotor holder. It can bear large radial and axial loads, thus ensuring the main rotor swing hinge function efficiently offering more long-range impact. This design applies all the best innovations while retaining the tried-and-true foundational design.

Two types of main rotor holder arms respectively correspond to different flight sensitivities. This design allows for the flier to choose according to demand. Pilots of all levels can choose products according to the accuracy of the control requirements and their own skill levels.

High precision injection molded horizontal axis positioning rubber ring, and a double layer polyurethane rubber ring with a double layer hardness of 95° is included in this design. Plus, a specially designed transverse rubber spacer for added safety. These design innovations effectively reduce the rotor part vibration, bring in swing hinge effect, and meet the stringent requirements of flight load bearing.

To adapt to the current mainframe load requirements of the swashplate, the stout swashplate also uses double row angular contact bearings. The inner utilizes high-precision fisheye bearings. All linkage ball threads have been increased to 3.0mm to avoid the design flaw of small size threads slipping ease.

As such, the Armor 700 long ball head design enlarges the sphere diameter to 5.8mm. Moreover, the specially customized 5.8mm ball link enables a clear design that avoids most helicopter linkage ball interference phenomena on the market.

The precision of the main shaft is Φ15MM with laser ruler reaches Φ14.990MM. This design innovation was made because, in addition to convenient visual positioning when installing synchronous main gear, it also enables the spindle fixing ring to have better friction fixing.

In 2010, we pioneered the introduction of an integrated spindle bearing mount, which ensures concentricity and reduces fuselage vibration (TL45088). New refinements continue to use this excellent design, with the upper and lower bearings adopt angular contact bearings.

Standard stainless steel explosion-proof ball link;

Standard fragile metal servo arm;

Floating anti-rotation bracket design;

All wiring have protective measures.

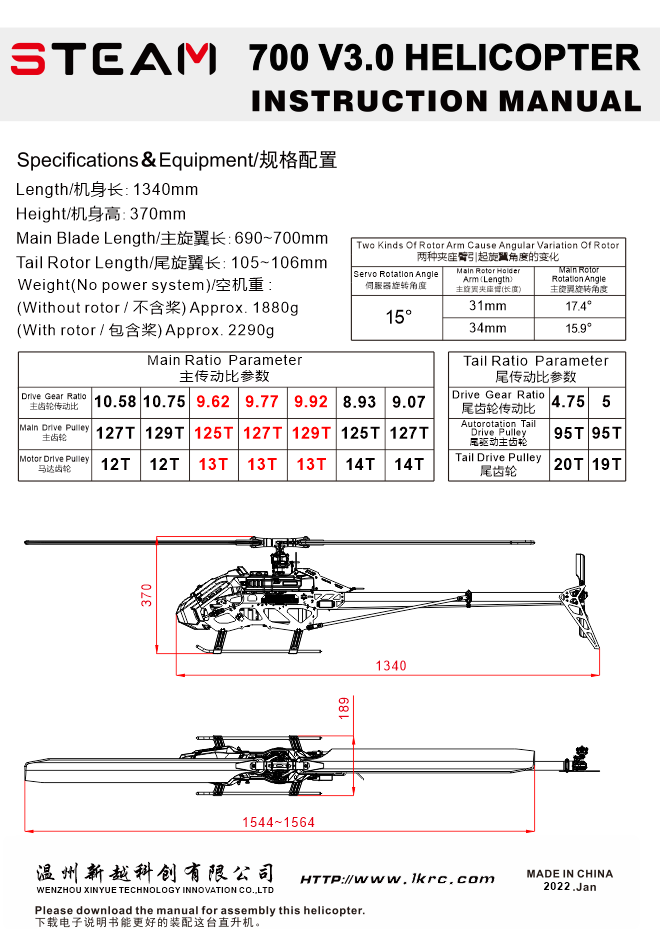

Compared to other helicopters, Armor 700 is equipped with three large kinds of main gear —125T/127T/129T/ — and three kinds of the motor pinion gears. In the effective range of tooth ratio, these changes enable the formation of denser transmission ratio parameters. This alignment better corresponds to different KV values of the motor, and in turn make full use of the full performance of the motor.

The main gear is processed by high-precision CNC hobbing. Overall, this enhances the tenon and mortise design of the frame, resulting in the lighter and stronger structures required by airplanes. The metal center mount uses a one-way overrunning clutch, and adopts a chock structure to hold the main shaft. Its locking force is four times that of needle type unidirectional bearing, which can tightly lock the main shaft.

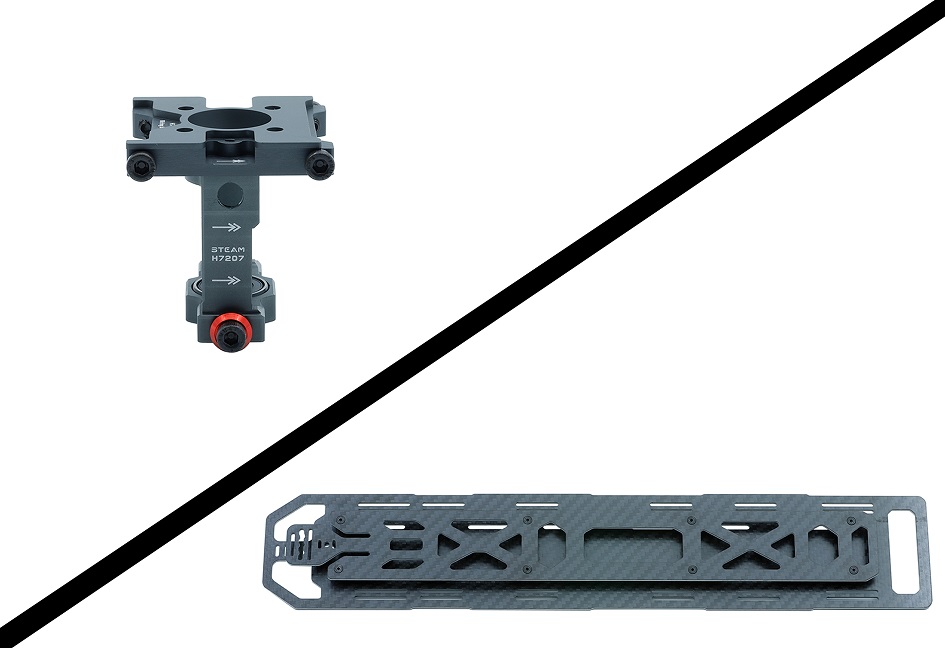

For being lighter, stronger, and creative, the Armor 700 adopts a new type of plate whose interior is made of composite materials. These design adjustments increase the compressive strength by about 5%. As a result, it weighs 20% less than pure carbon fiber. However, such refinements are not the result of cutting corners, as the material is expensive and used only for the battery tray and some parts in the kit. The new type of fuselage side plates needs to be purchased separately.

The upper and lower parts of the fuselage are connected by metal block mortise and tenon modules, which are unique to our design. These changes have resulted in a bidirectional embedded design. Within this innovative design, it only takes two screws to fix it in place for use with an 8mm diameter carbon fiber tail support assembly. The T-type structure, mortise, and tenon design, and the effective locking tailpipe, improves on flight stability and enhances the tail locking effect for a more comprehensive and long-lasting design.

Integrated chute panels and integrated motor mounts provide a lighter, more reasonable construction.

In December 2010, we launched the first integrated metal Tail Gearbox (TL2671) element. Now, many manufacturers have adopted this structure in an attempt to compete with our brand. This design upgrade has the advantages of a solid box structure and high concentricity of a tail shaft bearing position. As such, there is now a net increase in tail gear clearance adjustment, which means the tail shaft no longer has transverse clearance swing. This new design optimizes the press belt gear open installation and enables easy installation. With the new type of carbon fiber tail vertical, the overall weight is just 48 grams. By remaining at the forefront of this industry and leading by example, we will continue to exemplify innovation and ingenuity.

Manual Steam 700